Plastic Extrusions: Enhancing Effectiveness and Performance With Plastic Extrusions

Are you wanting to improve effectiveness as well as efficiency in your market? Look no more than plastic extrusions. With their key aspects and various advantages influencing efficiency, plastic extrusions are the remedy you require.

In this post, we will certainly explore methods for optimizing efficiency and developments that can take your operations to the following degree. Prepare yourself to uncover real-life study showcasing the effective application of plastic extrusions.

Don't lose out on this chance to reinvent your company.

Benefits of Plastic Extrusions in Enhancing Performance

You can greatly enhance your performance with plastic extrusions. These flexible components supply numerous advantages that can enhance performance in different markets.

Plastic extrusions are lightweight, making them very easy to deal with and also mount. Whether you are in the building, automobile, or product packaging industry, this function allows for fast and easy assembly, conserving you valuable effort and time.

Furthermore, plastic extrusions are very customizable, allowing you to tailor them to your details demands. With the capacity to create complex sizes and shapes, you can maximize your processes and make best use of productivity.

In addition, plastic extrusions are known for their toughness as well as resistance to tear as well as use. This implies that when set up, they need minimal maintenance, decreasing downtime and also boosting your total functional performance.

Furthermore, plastic extrusions offer outstanding thermal and also electrical insulation residential properties, making them appropriate for a variety of applications. From cord monitoring to weatherproofing, these parts can assist enhance your operations as well as enhance performance.

Trick Elements Affecting Performance in Plastic Extrusions

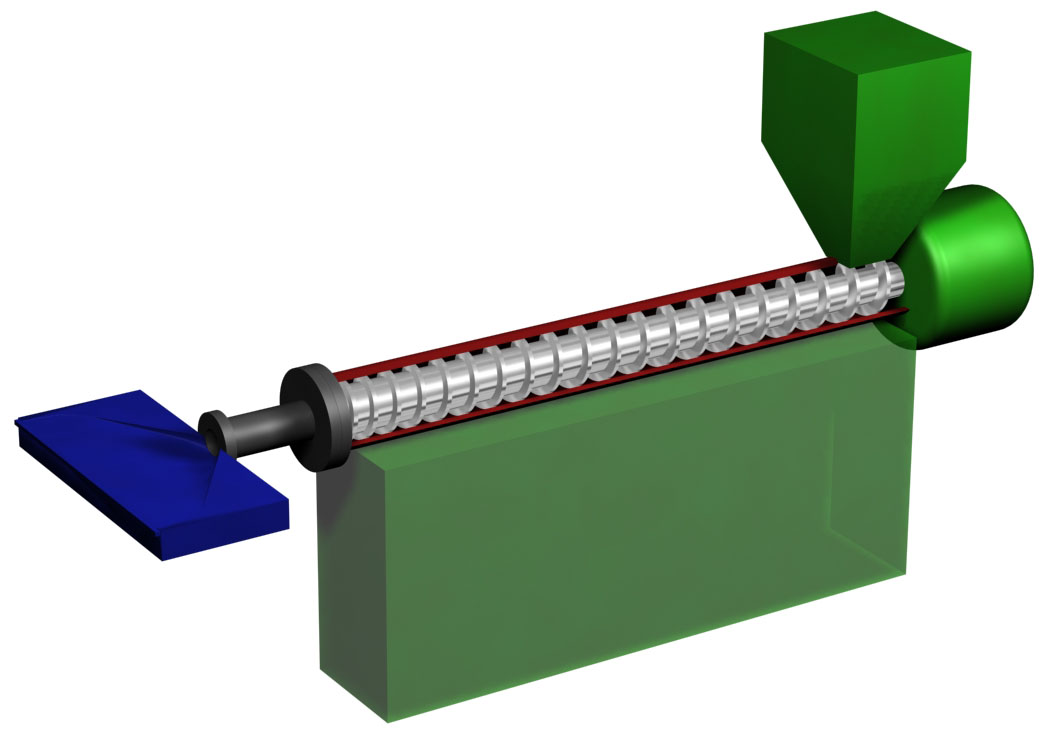

Among the vital factors that impact efficiency in plastic extrusions is the appropriate selection of products. Picking the right products is important for accomplishing ideal efficiency as well as performance when it comes to plastic extrusions. The kind of product utilized can significantly influence the extrusion procedure, in addition to the quality and also longevity of the last product.

By picking materials that have the appropriate homes and features, you can guarantee that the extrusion process runs efficiently and successfully. For instance, making use of products with good warm resistance can prevent melting or contortion during the extrusion procedure. Materials with high toughness and also resilience can result in a final product that is solid and also long-lasting.

An additional important aspect to consider is the compatibility of the materials with the extrusion devices. Various products may need various handling criteria, such as temperature and also rate, to attain optimal outcomes. Picking products that are fit to the specific extrusion devices being utilized can aid stop issues such as blocking, irregular circulation, or poor product high quality.

Along with material option, other elements such as die style, processing conditions, and also driver competence likewise play a role in the performance of plastic extrusions. By starting with the proper option of products, you can establish a solid foundation for attaining high-quality and efficient extrusions.

Methods for Maximizing Effectiveness in Plastic Extrusions

To enhance effectiveness in plastic extrusions, it is essential to very carefully think about aspects such as die design, processing conditions, and operator expertise. By concentrating on these essential locations, you can substantially boost the efficiency and also performance of your extrusion procedure.

Allow's speak regarding pass away style. The layout of the die plays an essential role in figuring out the high quality and also uniformity of the extruded plastic. It's important to make certain that the die is properly made, with the ideal dimensions and form, to attain the wanted item specs. In addition, considering variables such as land size, land clearance, and also leave angle can assist in minimizing waste and also improving the general effectiveness of the extrusion procedure.

Next off, allow's review handling problems. Pressure, speed, as well as temperature level are critical aspects that influence the extrusion procedure. Effectively controlling these variables can assist in accomplishing uniform melt circulation and avoiding issues like melt crack or product flaws. It is essential to check and also readjust these problems to maximize the performance as well as efficiency of the extrusion procedure.

Finally, driver competence plays a considerable role in making the most of efficiency. Well-trained drivers can identify and repair issues promptly, making sure smooth operation and very little downtime. Providing appropriate training and recurring support to your operators can boost their abilities and understanding, leading to enhanced effectiveness and also efficiency.

Developments in Plastic Extrusions for Boosted Efficiency

Staying updated on the most recent innovations is crucial when it comes more helpful hints to improving the performance of your plastic extrusion procedure. Technology is constantly progressing, and also brand-new improvements in plastic extrusions can assist boost the efficiency as well as performance of your procedures.

Among the current advancements in plastic extrusions is making use of innovative air conditioning systems. These systems ensure that the extruded plastic is rapidly cooled down as well as strengthened, leading to higher manufacturing rates and also boosted product high quality. By incorporating these cooling systems into your process, you can decrease cycle times and boost performance.

By fine-tuning these specifications, you can maximize the extrusion process and attain regular and precise results. This not only boosts product top quality yet also lowers waste and also decreases downtime.

In addition, improvements in product formulas have actually led to the development of brand-new high-performance plastics. These plastics use better stamina, durability, and warmth resistance, making them suitable for a large range of applications - extrusion of plastics. By utilizing these innovative products, you can improve the efficiency as well as capability of your items

Study: Effective Implementation of Plastic Extrusions for Efficiency and Performance

Taking a look at successful study can offer important insights on exactly how applying plastic extrusions has improved efficiency and efficiency in various markets.

One such study comes from the vehicle industry. Making use of plastic extrusions in the production procedure has actually considerably minimized manufacturing time as well as boosted general performance. By replacing standard metal elements with plastic extrusions, producers streamlined their processes as well as accomplished cost savings.

An additional study comes from the building and construction market. Plastic extrusions have actually been used to enhance the performance of doors and also windows. By utilizing plastic extrusions as opposed to standard materials like wood or steel, manufacturers created items that are extra sturdy, weather-resistant, and also energy-efficient. This better efficiency as well as decreased upkeep expenses for home owners and building proprietors.

In the product packaging market, plastic extrusions have revolutionized how products are packaged as well as shielded during visit this site right here transportation. Custom-designed plastic extrusions have actually allowed suppliers to produce lightweight product packaging options that supply premium defense against damages. This has decreased the danger of product damages throughout transportation and lowered delivery prices for firms.

Verdict

There you have it âEUR" plastic extrusions are a game-changer when it comes to enhancing effectiveness as well as efficiency.

By optimizing essential factors as well as carrying out ingenious methods, services can greatly enhance their operations. Whether it's decreasing waste, boosting performance, or attaining cost financial savings, plastic extrusions supply an option.

Don't just take our word for it, there are numerous successful study that show the effectiveness of plastic extrusions.

So why wait? Begin exploring the advantages of plastic extrusions today and also take your performance see here and also performance to new heights. extrusion of plastics.

With their vital elements and also numerous benefits affecting performance, plastic extrusions are the option you require.

One of the key variables that impact efficiency in plastic extrusions is the appropriate selection of materials. When it comes to plastic extrusions, picking the ideal products is crucial for accomplishing optimal efficiency as well as efficiency. The usage of plastic extrusions in the manufacturing process has actually considerably decreased manufacturing time and also increased general effectiveness. Plastic extrusions have been utilized to boost the efficiency of windows as well as doors.